SPC Flooring

PRODUCT DESCRIPTION

| Product Name | SPC Flooring |

| Thickness | 3-6 mm or Customized |

| Back foam | IXPE,EVA 1mm, 1.5mm, 2mm |

| Main series | Wood grain, Marble stone grain, Herringbone, Fishbone or Customized |

| Wood grain | Oak, Birch, Cherry, Hickory, Maple, Teak,Antique, Mojave, Walnut, Mahogany, Marble effect,Stone effect, White, Black,

Grey or as required |

| Core material | 100% new virgin PVC material and stone powder |

| Green rating | E0, Formaldehyde free |

| Package | Standard packaging |

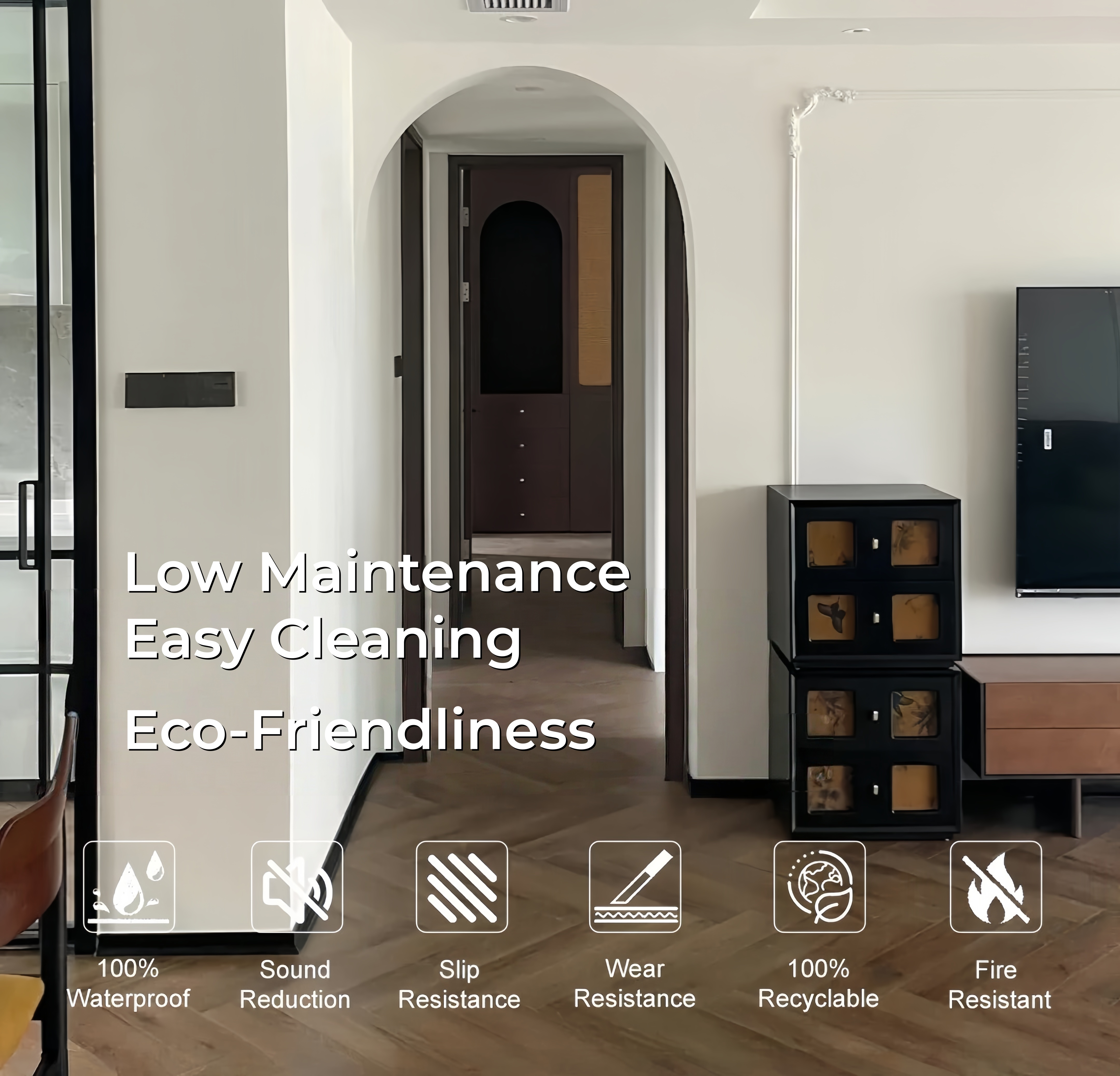

| Advantages | Waterproof, fireproof, wear-resistant, non-slip, scratch-resistant, easy to install |

| Application | Office, Hotel, Shopping mall, Celling, Home |

SPC Flooring VS Other Flooring

| Feature | SPC | Solid Wood | Laminate |

| Durability | Excellent (scratch/impact-resistant) | Poor (dents/warps) | Moderate (peels) |

| Water Resistance | 100% Waterproof | Poor | Poor |

| Maintenance | Low (wipe clean) | High (refinish) | Moderate |

| Stability (Humidity) | Excellent | Poor | Poor |

| Comfort/Acoustics | Good (with underlay) | Good | Poor |

| Long-Term Cost | Cost-Effective | Expensive | Affordable (short-lived) |

Installation Methods

The installation is simple and easy.

The effect is simple and natural, suitable for any apartment.

This style is classic and retro, with a sense of layering,

suitable for visually stretching small spaces.

The cost is higher than straight lay.

This method has smooth lines and is suitable for corridors, long living rooms, etc.

It is the preferred choice for those with sufficient budget and pursuit of design sense.

Product display

1. Install the cabinet first, leaving space at the bottom equal to floor thickness plus moisture-proof pad. The floor panel slides directly under the cabinet, eliminating edge strips for a cleaner look. If the cabinet is already in place, use L-shaped edge strips to cover gaps.

2. Bedroom door gap: In fully furnished homes, original door clearances may be too low after adding SPC flooring and moisture-proof pads, risking jamming. Adjust by trimming the door bottom or slightly undercutting the door frame to avoid cutting the entire door. Trimming 2 cm is an option, but control dust and protect door paint during operation.

3. Floor flatness: Inspect the existing tiled floor for hollowing and uneven areas. Correct local irregularities with self-leveling compound or moisture-proof pads. SPC flooring requires high flatness (within 3 mm deviation); otherwise, it may produce noise when walked on.

4. Tiling direction: Herringbone patterns incur 8–10% material waste. Plan quantity accordingly and start installation from the living room centerline for optimal visual balance.

Precautions: It is recommended to choose waterproof SPC for the balcony area and seal the joints with glue. Place the floor on site 24 hours before laying to adapt to temperature and humidity. Use T-shaped strips of the same color or extremely narrow edge-pressing strips for edge finishing to avoid abrupt changes.

Suggestion: The floor laid with herringbone has a high appearance level, but the labor cost is expensive (about twice that of ordinary laying). If the budget is limited, straight board laying can be considered

You May Need

Hot Selling

Send Us A Message

Get Price And Free Samples Right Now!

-

Phone

-

E-mail

-

WhatsApp

Send Us A Message

Get Price And Free Samples Right Now!